Sale of valves for use in the oil and gas sector

28000 Series VariPak* Micro-Trim Globe Valve

Designed specifically for low flow applications, the Masoneilan Varipak Control Valves provides excellent throttling control performance with a wide range of options and capabilities. Design optimization has also resulted in an extremely integrated and compact assembly.

Key features and benefits of the VariPak control valves include:

- Heavy Top-Guiding Rugged

- Application Flexibility

- Adjustable CV

- Compact Assembly

- Anti-Cavitation Trim

- Design flexibility

Sizes: 1” (25 mm) standard 1/2” through 3/4” (15 through 20 mm) available on request

Ratings and Connections:

• Flanged: ANSI 150 – 600

• Flangeless for mounting between flanges:

ANSI 150 – 2500

UNI-DIN 10 – 400

• Screwed: NPT 1/2” through 1”

(15 through 25 mm)

Body Materials:

• Stainless steel

• Monel

• Hastelloy C

• Alloy 20

Actuator:

• Integral spring diaphragm

Trims:

• Full stellite needle plug

• Multistep trim available

Inherent Characteristic:

• Linear

SVI II ESD Emergency Shutdown Device

The SVI II ESD is a SIL3 capable partial stroke test controller and emergency shutdown device.

Its safety and PST function are independent of each other, allowing the device to respond to a safety function while a test is active.

It can capture two shutdown events and allow continuous HART communications during a trip facilitating local panel annunciation using the built in discrete outputs.

The SVI II ESD automatically captures and stores the PST results in its non-volatile memory while Valvue ESD software regularly interfaces and updates its database with PST and full stroke data.

Communication / Control Platform:

• 24Vdc or 4-20mA Safety function trip signal (SIL3)

• HART® and Switch(Discrete Output) fault annunciation

Pneumatics:

• 20 – 120 psi Supply pressure

• Single-acting

Operating Temperature:

• -40ºC to +85ºC

Materials:

• Aluminum (painted) or Stainless Steel Housing

• Composite Polymers and Stainless Steel Pneumatics I/O:

• 4-20mA output and discrete Input

Mounting / Feedback:

• Non-Contact magnetic position feedback

• Rotary or Linear

• Stainless Steel brackets for all Masoneilan and major valve brands

Certifications:

• Explosion / Flame / Dust-proof and Intrinsically safe

• FM, CSA, ATEX, IECEx

• Regional – NEPSI, Taiwan TS, CCOE, CU-TR, AZS, UZ, INMETRO, JIS, KOSHA, IA

Diagnostics:

• Partial Stroke Testing (PST)

Configuration / Monitoring Interfaces:

• Local Display with Pushbuttons

• ValVue* ESD Device Diagnostic and Configuration Tool

• DTM or eDDL – seamless integration into leading asset management systems

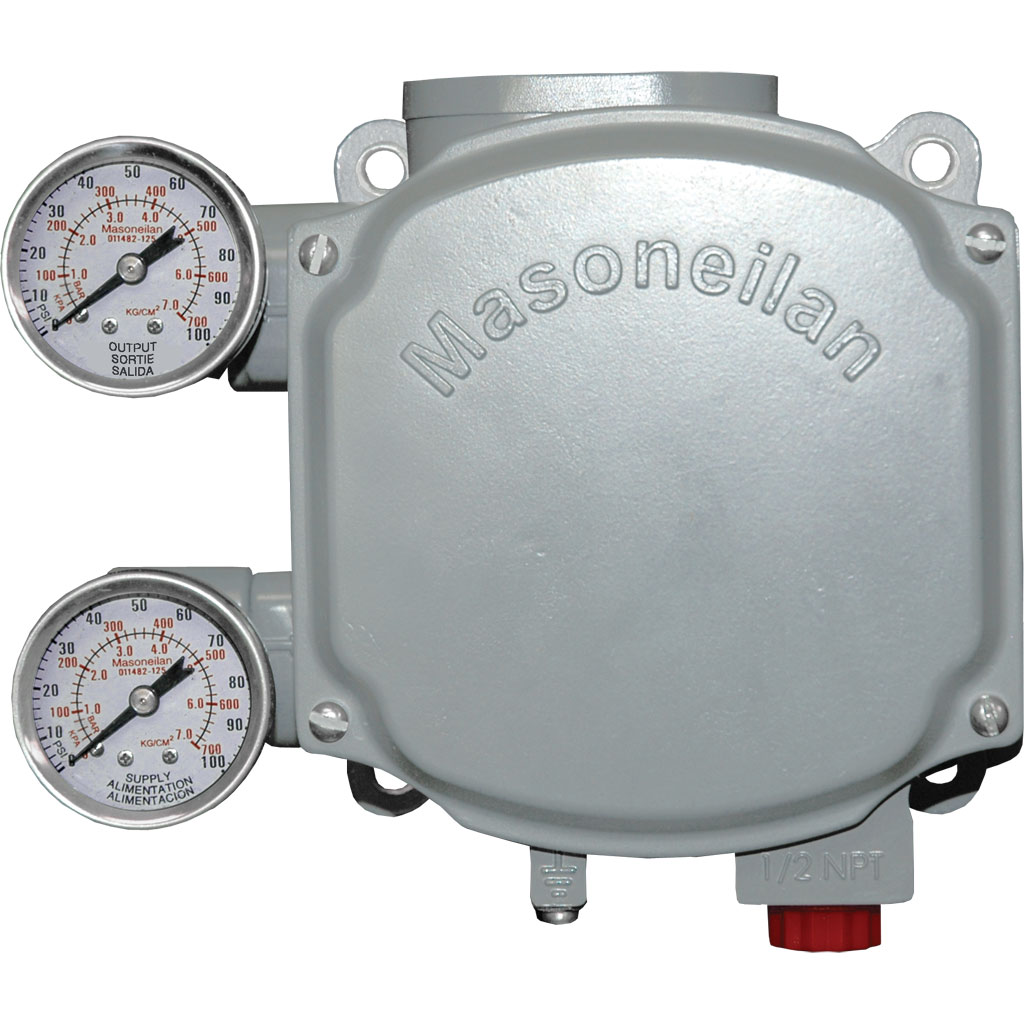

SVI II AP Advanced Performance Digital Valve Positioner (HART)

Supporting HART communications over the 4-20mA signal, the SVI II AP digital valve positioner is suitable for control systems with 4-20mA signaling.

Certifications:

ATEX, FM, IEC, GOST, NEPSI, KOSHA, INMETRO, JIS and CSA approvals. Explosion proof, intrinsically safe and dust protection.

Communication Platform:

HART revision 5 or revision 7 (field selectable)

Signal – Supply:

4-20 mA control signal No external power required Supply pressure: 20 – 150 psi (1.4 – 10.3 bar)

SVi1000 Digital Valve Positioner

The SVi1000 is a user-friendly 4-20mA with HART® digital valve positioner for single-acting pneumatic control valves.

Leveraging many of the same technologies from the SVI II AP, the SVi1000 is perfect for those that need a low maintenance valve positioner, and an ideal candidate for upgrading legacy electro-pneumatic positioners.

Designed to be installed and operational in less than 5 minutes, the SVi1000 is easily through its “One button, one function” local pushbuttons or via its powerful DTM interface and ValVue* software.

Communication / Control Platform:

• 4-20mA with HART®

Pneumatics:

• 20 – 100 psi Supply pressure

• Single-acting

Operating Temperature:

• -40ºC to +85ºC

Materials:

• Aluminum (painted)

• Composite Polymers and Stainless Steel Pneumatics I/O:

• 4-20mA output or (2) Configurable Switches

Mounting / Feedback:

• Non-Contact magnetic position feedback

• Rotary or Linear

• Stainless Steel brackets for all Masoneilan and major valve brands

• Integrated magnet option for custom mounting

Certifications:

• Intrinsically safe / Non-Incendive / Limited Energy

• FM, FMc, ATEX, IECEx

• Regional – NEPSI, Taiwan TS, CCOE, CU-TR, AZS, UZ, INMETRO, IA

Diagnostics:

• Standard Continuous and Offline Diagnostics/Methods

Configuration / Monitoring Interfaces :

• User-friendly “One button, one function” local interface

• ValVue* Device Diagnostic and Configuration Tool

• DTM or eDDL – seamless integration into leading asset management systems

12800 Series Pneumatic Level Transmitter / Controller

The 12800 Series pneumatic level controllers are used to control and/or transmit the level in a tank with one or two fluids (interface service). The 12800 Series operates according to liquid displacement and torque tube principles.

Range:

14” through 120” (355 through 3048 mm)

Ratings and connections:

- flanged: ANSI 150 – 2500, UNI-DIN 10 – 100

- screwed: NPT-F (1 1/2”, 2”)

- welded

Body materials:

- carbon steel

- stainless steel

- chrome-moly

Displacer materials:

- stainless steel

- other materials on request

Torque Tube materials:

- Inconel

- stainless steell

- other materials on request

Action:

• Proportional

• Proportional + reset

• Transmitter

• Differential gap

• Duplex

49000 Series Globe and Angle Style with Lo-dB* or V-LOG* Trim

The 49000 Series V-LOG high pressure drop valve features an enlarged body gallery to accommodate gas expansion and up to 36 stages of pressure reduction via a stacked disk trim design. It offers optimized severe service solutions for high-pressure drop applications with potential damaging noise or cavitating fluid conditions. Built around the Masoneilan V-LOG Energy Management Trim, the 49000 Series is capable of handling a wide range of both liquid and gas services in a variety of process industries.

Benefits of the 49000 Series V-LOG high pressure drop valve include:

- Compared to forged or fabricated bodies, the cast globe-style body of the 49000 Series offers lower in weight and overall dimensions which helps reduce installation costs.

- Enlarged body galleries and expanded outlets provide velocity control for expanding gases.

- Galleries sized to accept “typical” V-LOG trim dimensions for a standardized body platform and an optimized solution.

- V-LOG trim for use with either compressible or incompressible fluids under severe service conditions.

- V-LOG and Lo-dB trim provide reduced noise and cavitation that could negatively affect the valve and/or surrounding equipment.

The V-LOG Trim can be configured for use with either compressible or incompressible fluids under severe service conditions making the 49000 Series valve a superior choice for liquid and gas applications including:

- Boiler feed water start-up and control

- Steam letdown

- Pump discharge

- Water reinjection

- Gas recycle

Sizes:

4” through 36”

(100 through 900 mm)

Ratings and Connections:

• Flanged: ANSI 150-2500

UNI-DIN 10 – 400

• Welded: BW

Body Materials:

• Carbon steel

• Stainless steel

• Chrome-moly

Actuators:

• Model 87/88 multi-spring diaphragm

• Model 51/52/53 piston cylinder

Trims:

• Single or double stage Lo-dB and V-LOG energy management trim available in low noise flow-to-open designs or anticavitation

flow-to-close variety of balanced trim options for Class IV and V shutoff

Inherent Characteristic:

• Linear or equal percentage

Chemical

Chemical  Corrosive Service

Corrosive Service  Erosive Service

Erosive Service  Fugitive Emissions Control

Fugitive Emissions Control  General Service

General Service  Mining

Mining  Oil & Gas

Oil & Gas  Power Plant

Power Plant  Pulp & Paper

Pulp & Paper  Refinery

Refinery  Severe Service

Severe Service  Water / Wastewater

Water / Wastewater